Services

Comprehensive support for every project phase.

R&D One-Stop-Shop

We develop side by side with the R&D departments of our customers

Our R&D experts work across locations and side by side with our customers’ R&D departments to develop the best possible products or technologies.

Services

Our Services

The starting point for SAG R&D could be installation space, boundary conditions or specifications. The R&D process leads to a virtually and physically tested prototype that is ready for use or further testing at the customer’s site. Also comprehensive real tests can be carried out in the well-equipped SAG laboratories.

Product development of structural components, lightweight parts and assemblies

Alloy development for aluminium

Development of heat treatment strategies for aluminium alloys

Joint development of material and component

Planning of series production lines and systems for the manufacture of lightweight aluminium components and assemblies

Physical testing of prototypes according to customer specifications

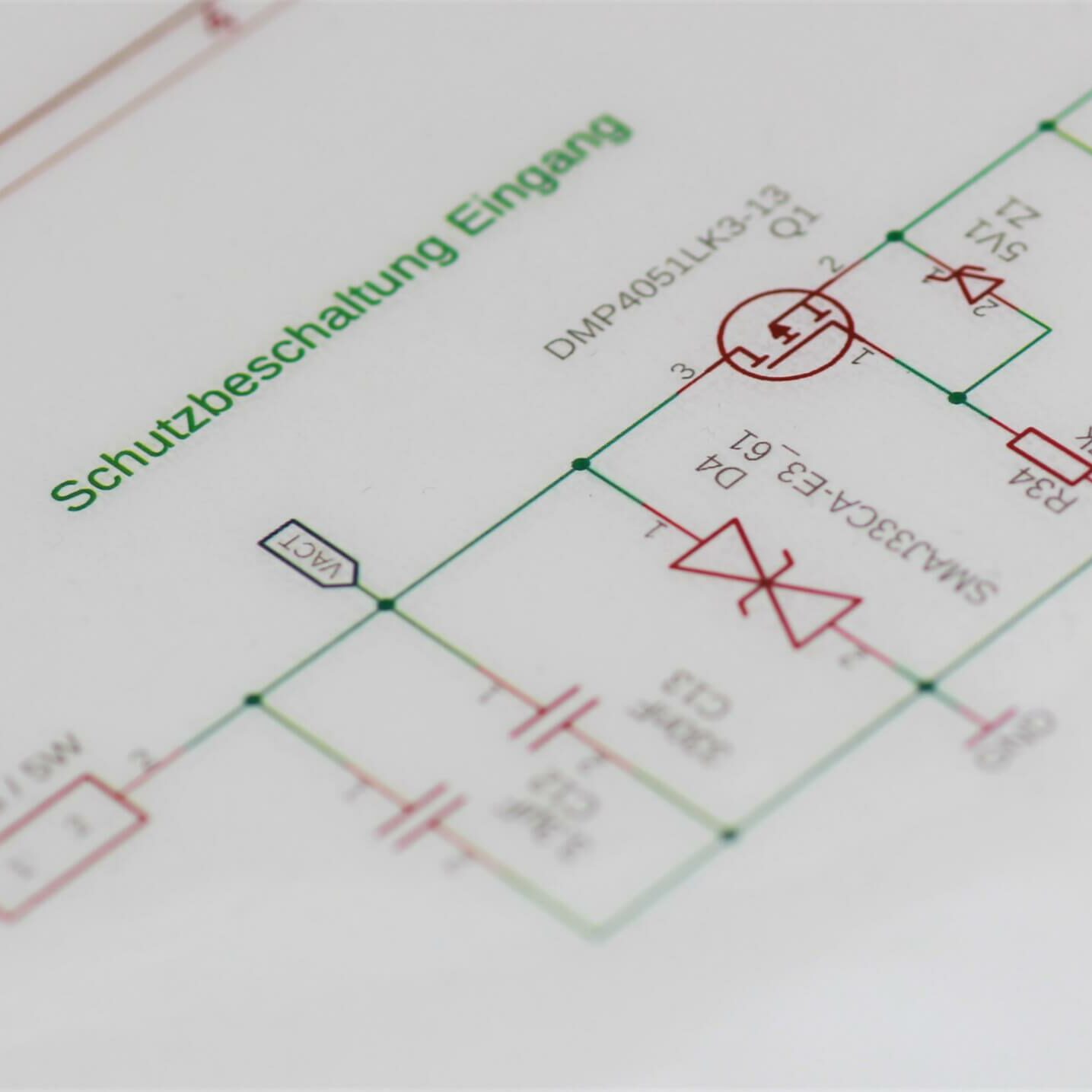

The following services are offered by SAG R&D in the development of fuel tanks and compressed air tanks:

SAG R&D is also a professional partner with excellent know-how in the development of efficient production processes and manufacturing concepts.

- Real testing of fuel tanks

- crash simulations

- Thermal and thermomechanical simulations

- Sheet metal forming and casting simulations

- Motion simulations in fuel tanks

- FEM strength calculations

- fatigue calculations

- Strength calculations of fuel tanks

- Development of tanks according to specific guidelines

- Development of tanks for LNG (Liquefied Natural Gas)

- Development of smart tanks with electronic sensors

- Research on tank solutions for liquid hydrogen

Main focus

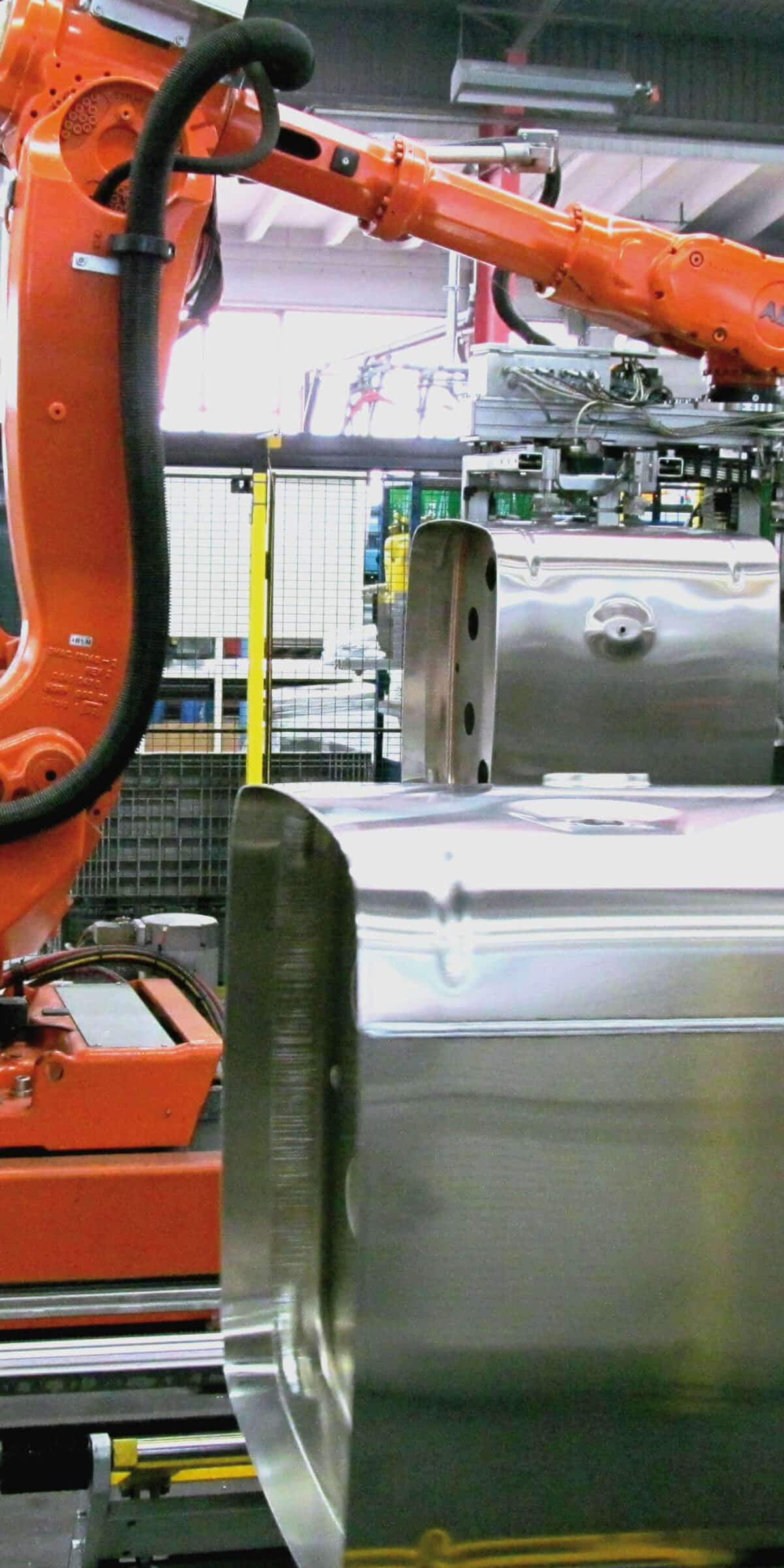

SAG’s strengths in process and manufacturing technology:

- Robot-based automation, SPS technology

- Automation of connection technology

- forming

- Automated leak testing (He-based) of pressure-tight components

- Inductive heating processes

- Concepts and implementation of production jigs and fixtures

- process linkages

Contact

Get in touch

- We will get back to you promptly

"*" indicates required fields