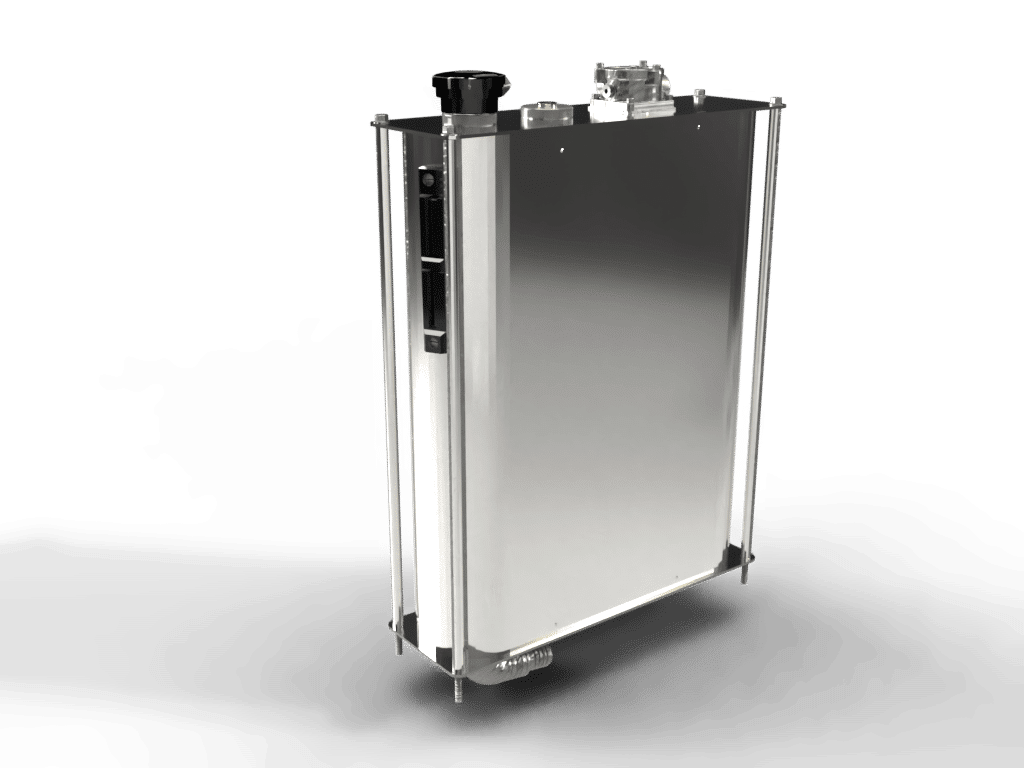

The requirements for competitive tank solutions are high: they must meet the high quality standards of the OEMs, yet be cost-efficient and are tailored to the specific structural requirements. For the SAG R&D experts, this is a wide field of activity for developing special solutions with additional benefits for the benefit of the customers.

A recent example of “added value” in the development of a hydraulic tank for the market: SAG Fueltech Sweden developed a new design for a hydraulic tank mounted behind the truck cabin. Thanks to the changed cubage, production costs can be saved, which in turn strengthens the customer’s competitiveness.

Lateral thinking for customer-specific solutions

The SAG R&D team generated ideas on how to minimize material and production costs through design changes. The considerations were based on findings from interviews which SAG conducted with the customer on the desired properties of the tanks – also in relation to the competitive situation on the market. The result of the development process speaks for itself, as Mikael Jönsson, CEO of SAG Fueltech Sweden, illustrates: “The relaunch of the design resulted in a considerably production cost saving. The lower price also makes the customer more competitive”. On the basis of this new product design, SAG has now developed further tanks with a volume of 100 to 250 litres and successfully brought them into series production.

Share this article

News

you might also like

Stay up to date with the latest developments at SAG. From groundbreaking innovations to industry insights and company milestones, our news section keeps you informed. Explore our latest updates and see how we’re shaping the future.

Growth market in sight: SAG Group wants to start production of cryogenic tanks and lightweight components in India

The SAG Group, an international producer of aluminum tanks and lightweight components as well as a pioneer in the field of cryogenic tank technology for commercial vehicles, is preparing to expand into India. At the heart of the plans is a strategic partnership with an Indian manufacturing company in the state of Maharashtra. The plan […]

Read article

Investment for innovation: SAG Group establishes R&D center for Rheocasting

The SAG Group will build a research and test center for Rheocasting technology at its founding site in Lend/Salzburg in the coming months. The development center, which is scheduled to start construction in January 2025, will include test facilities, a laboratory and office workstations. Extensive testing and research will be possible to further perfect Rheocasting […]

Read article

Bonfire test confirms safety of the SAG LH2 tank system even in extreme conditions

The liquid hydrogen tank system for trucks developed by SAG has reached a decisive milestone on the way to approval for road traffic: the successful completion of the so-called Bonfire test. This special fire safety test is a mandatory test to obtain type approval from the Federal Motor Transport Authority in order to ensure the […]

Read article

SAG GROUP